Welcome to

FUTABA JTW (THAILAND) LTD.

We produce the Mould base, Die Set, Precision Plate, Mould Marshalling, Hot Runner and Components with selecting raw-materials with high quality under the strictly quality control from mill factory, thus able to trust with variety of kind and size of our products and also respond the customer special specification by using the short time of delivery .

【※※ IMPORTANT ANNOUNCEMENT ※※】

Please beware of fraudulent emails regarding changes to transfer details.

We have received reports of fraudulent emails being sent, pretending to be from our company, ins tructing users to "change their transfer destination."

These emails have no connection to our company and are intended to commit fraud.

Request to Our Customers

・ We will never send you an email informing you of any changes to our bank account.

・ If you receive a notice regarding a change in our bank transfer details, please call us to confirm before making the transfer.

・ If you receive a suspicious email, do not click on any links or open any attachments.

Contact us :

If you receive a suspicious email or have any questions, please contact our sales office below.

TEL: +66 3852 2271-4

E-Mail: salesfutaba@fjthai.com

Futaba JTW (Thailand) Ltd. is a company of Futaba Group.

Futaba is a long-standing manufacturing with over 70 years of history in plastic mold and metal mold products. Futaba JTW was established in Thailand in 1998.

-

Use reliable materials from Japan

We will deliver stable and high-quality steel by purchasing from major Japanese steelmakers.

-

There are various steel grades available for use.

Futaba have many grade of steel for you choose more than 40 types.

You will definitely get the grade of steel you want.

We also provide advice on steel grades free of charge. You can ask to our.

Many customers have trusted our services.

Products

We are many quaulity products support requirement your business.

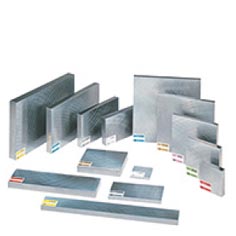

Precision Plate

Selecting raw material with high quality under the strictly quality control from the mill factory, using the high technology of production, thus also able to trust with variety of kinds and sizes and also able to respond the customer's special specifications with using short time of delivery which can respond all of customer's purpose.

Mould Base

Able to reduce the Designing and Production processes for Moulds by using short time of delivery and selecting raw material with high quality. By using the high technology and also able to respond the customer's special specifications

DIE SET

Able to reduce the Designing and Production processes for Press Dies by using short time of delivery and selecting raw material with high quality which is an international accepted level with variety of kinds and sizes. Also is able to respond the customer's specifications.

MOULD&DIE COMPONENTS

Many kinds of spare parts for Mould and Press Die, by selecting raw material with high quality and high level of quality control processes, short time of delivery. Able to use for assembly in both of new production and maintenance jobs.

HOT RUNNER SYSTEM

It is a method of the runnerless system where there is no need for the sprue, runner to harden and remove in every injection cycle, with the plasticizing "resin flow path" flowing into the product with an injection machine. In general plastic injection molding, it is a system that maintains the resin flow by heating the resin flow path from the sprue to the gate with an electric heater.In the hot runner system, there is an open gate system without valves and valve gates system that can close the resin flow. By forcing it by creating a valve structure in the gate cavity.

MOULD MARSHALLING SYSTEM

Able to check the condition of the pressure inside the mold in real time. Standard waveforms are recorded. (Normal waveforms) and use an alarm. From waveform variations to detect abnormalities and determine injection conditions.

Contact Us

Address

78 Moo 2 Wellgrow Industrial Estate, Bangan-Trad Road, Tambon Pimpa, Bangpakong District, Chachoengsao 24130 Thailand.

Call Us

+66 3852 2271-4 fax: +66 3852 2275

Email Us

salesfutaba@fjthai.com